Precision Manufacturing, Safeguarding Health – The Journey of Sanitary-Grade Stainless Steel Butterfly Valve Production

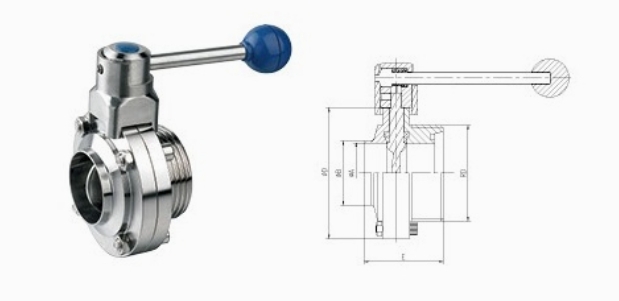

In industries with stringent hygiene requirements such as food, pharmaceuticals, and biotechnology, the reliability and cleanliness of every pipeline connection directly impact product quality and user safety. As a critical component for fluid control, sanitary-grade stainless steel butterfly valves have become the "guardians" of modern production lines, renowned for their corrosion resistance, easy cleanability, and leak-proof performance. Let us take you behind the scenes to explore how these high-quality valves are meticulously crafted from raw materials to finished products.

The essence of a sanitary-grade butterfly valve lies in its compliance with hygiene standards. The process begins with selecting 316L or 304L stainless steel that meets international certifications (FDA, 3A, EHEDG). These materials offer exceptional resistance to acids, alkalis, and oxidation, while their ultra-low carbon content prevents intergranular corrosion after welding. Every batch of steel undergoes spectrometric analysis to verify composition, ensuring purity and safety from the very start.

The valve body is formed using advanced casting techniques like investment casting or lost-foam casting. A 3D-modeled, streamlined design minimizes fluid retention zones. Molten stainless steel, heated above 1600°C, is poured into CNC-machined molds. Post-casting, X-ray and penetrant testing eliminate defects like pores or cracks, ensuring structural integrity and long-term durability.

Critical components, including sealing surfaces and flange interfaces, are refined in temperature-controlled cleanrooms. Five-axis CNC machines achieve mirror-finish surfaces (Ra ≤ 0.8μm) for zero-leakage performance. Laser alignment tools maintain coaxiality accuracy within 0.05mm, guaranteeing smooth valve operation.

To meet full-bore sanitary design requirements, automated TIG welding under inert gas shielding ensures smooth, oxidation-free seams. Certified welders complete the process, followed by endoscopic inspections and passivation treatments to enhance corrosion resistance.

All fluid-contact surfaces undergo multi-stage mechanical and electrolytic polishing. Progressive grinding with varying grits achieves a surface roughness of Ra ≤ 0.4μm, compliant with food-grade standards. This inhibits bacterial growth and enables efficient CIP (Clean-in-Place) cleaning.

Every assembled valve must pass rigorous trials:

Airtightness Test: 0.6MPa compressed air, 30-minute pressure hold.

Cycle Endurance Test: Over 100,000 open-close simulations.

Certification: Third-party validation against GMP, ASME BPE, and other standards.

Traceability: Laser-etched unique IDs enable full production history tracking.

From raw steel to a guardian of hygiene, each step embodies our commitment to excellence. Our sanitary-grade stainless steel butterfly valves are more than industrial components—they are a promise of safety, efficiency, and trust.

Ensuring every drop flows with safety and purity.

—ONEMO Stainless Steel | 15 Years of Expertise in Stainless steel Solutions

Contact: Pershing

Phone: +8615858821847

E-mail: info@onemoss.com

Whatsapp:+8615858821847

Add: 71 Liuzhai Section, Luodongnan, Yongzhong Street, Longwan District, Wenzhou City

We chat